Chapter 5

RIPCORD

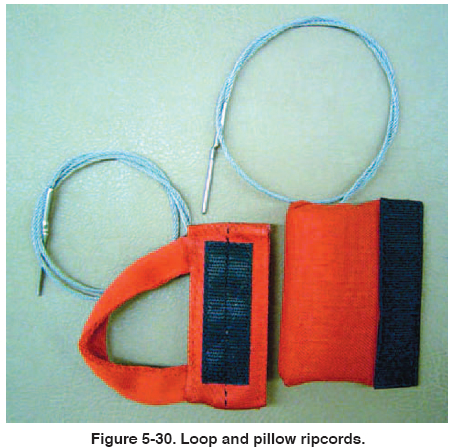

All the areas mentioned in the pilot emergency parachute

section apply to the sport rig. In addition, some assemblies

utilize a ripcord which has a webbing loop handle,

or a “pillow” type handle similar to the 3-Ring® release

handle. [Figure 5-30] It is important that the rigger check

these handles for proper markings and fit to the assembly.

Make sure that there is sufficient slack in the cable to

allow no loading of the pin in any attitude or position that

the wearer may conceivably get into. Most, if not all of

these style handles utilize Velcro® to secure them to the

harness. Make sure the Velcro® is in good condition for

holding ability but not so much as to inhibit the pull

force.

Remember, while both the pilot emergency parachute and

sport piggyback assemblies share many areas in common,

each has peculiar requirements for its use. It is

important for the rigger to recognize these and handle

each system accordingly.

RIGGING AND REPAIRS

When the entire assembly inspection is complete, the

rigger will have a list of the discrepancies found during

the procedure. At this point, a determination must be

made on how to remedy these defects. For senior riggers,

certain remedial action may be outside the scope of their

certificate. If so, those riggers need to find an appropriately

certificated and rated rigger to do the work, or

return the parachute to the manufacturer for repair. In the

case of major canopy or harness work, this may be the

best solution regardless. Aside from the qualification limitations

of the rigger, the manufacturer may be better

equipped to perform major repair or overhaul. They have

the original patterns, templates, and design data as well

as the certified materials. In addition, their labor rate is probably less than what the rigger may charge the customer,

particularly if he/she has not done this repair

before. The factory has the experience and practice that

will result in the repair looking “just like new.” While

some riggers may look at any given project with anticipation,

they also need to look at what is best for the

customer.

Many times, the master rigger has a repair facility and

stocks it with the necessary materials. In most cases,

these materials come from sources with no traceability

as to their origin. The manufacturer is required to use

only those materials that have been tested, certified, and

approved to meet the standards of their quality control

system under the TSO system. During one recent routine

inspection and repack, the rigger found severe failure

of the harness stitching at the main lift web/leg strap

junction. Upon further examination, it was determined

that the thread used to sew the harness was not nylon.

The harness was returned to the manufacturer, who then

determined that the thread was indeed cotton and not

the required nylon. The thread broke at approximately

10 pounds vs. 45 pounds for 5-cord nylon. Further

investigation revealed that the harness was originally

manufactured with a harness size 3 inches shorter.

There were telltale marks left from where the original

harness was stitched. This modification was evidently

performed by someone who either was not qualified to

perform the work or had gotten a batch of the wrong

thread by mistake and did not recognize the difference.

Attempts to find out who did the alteration were unsuccessful.

The manufacturer repaired the harness at no

charge and returned it to the customer. To preclude this

type of problem, many professional riggers and lofts

establish good working relationships with the manufacturers

and procure certain materials from them. They

keep these marked and in a separate area, and use them

only on the appropriate projects.

Another area of concern is a master rigger who does

major alterations without proper approval of the manufacturer.

The rigger may do major repairs to return the

assembly to its original condition without further authorization

of the Administrator or manufacturer, but alterations

are another story. 14 CFR, subsection 65.129(e)

states that “No certificated parachute rigger may pack,

maintain, or alter a parachute in any manner that deviates

from the procedures approved by the Administrator or the

manufacturer of the parachute.” There are a number of

common alterations seen in the field. Among them are:

harness re-sizing, AAD installations, RSL retrofits, chest

strap relocation, and others. The manufacturer’s approval

can vary from a verbal message over the phone to a formal

engineering procedure complete with drawings and

specifications. If the work is done correctly, the truth

probably lies somewhere in the middle. If riggers want to

ensure they are following code, they should obtain some form of written approval from the manufacturer in whatever

form they will provide.

The bottom line is that the purpose of the system is to provide

an infrastructure that ensures the safety of the public.

Professional riggers strive to do the “right thing” both

morally and legally.

|