Chapter 5

STRAIGHTENING THE CANOPY

If a rigger finds lines out of sequence or the canopy is

inside out, it becomes necessary to remove any twists,

tangles, or turns. There are two things to remember when

encountering this situation. First, if the parachute was

originally straight and the entanglement occurred from

handling, it is possible to untangle the parachute without

disconnecting anything. Second, if the parachute was

assembled incorrectly in the first place, it will be virtually

impossible to straighten it without disassembling it.

These two scenarios become particularly acute when the

rigger is brought a parachute for repacking and it was

assembled incorrectly. At first the rigger assumes it to be

correct, but when a correct continuity cannot be done, it

becomes very frustrating, and the rigger may spend an

excessive amount of time trying to straighten the canopy.

The rigger should always start at the top or apex end of

the canopy. Make sure that the top gore with the data

panel is facing up. Follow the gore to the apex so that the

upper lateral band is on the outside. Attach the apex to the

upper tension device. Next, flake the gores in sequence to

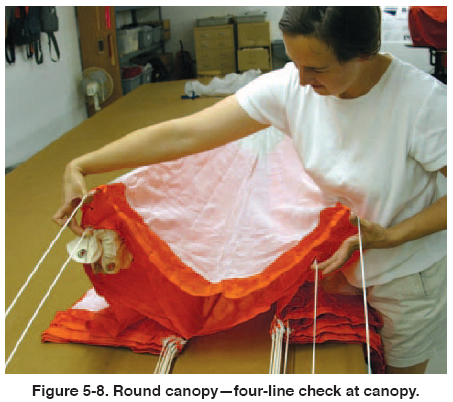

see if the canopy is straight. Split the canopy so the left

and right line groups are separate at the skirt of the

canopy. [Figure 5-7] Pick up the two center gores and

grasp the four lines. [Figure 5-8] These will be line

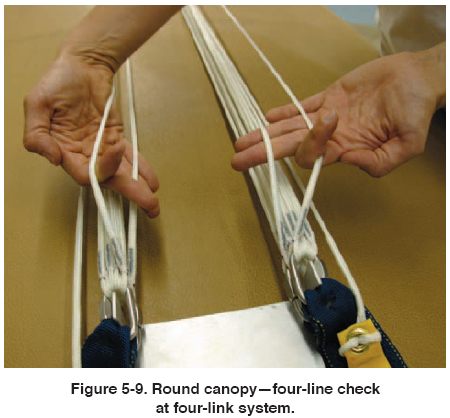

number 1 and the last line of the sequence. Run these

lines down toward the risers and/or container. On most

canopies, these lines will run to the inside, top connector link of a four-link system or to the inside of a two-link

system. [Figure 5-9] If these lines are correct, continue

the checking of the line continuity.

If the lines are not straight, release the risers from the harness,

if possible. If not, take one of the two top lines and

untangle it until the line runs straight back to the canopy

without going around any of the other lines. Untangle the

risers and harness/container until the rest of the lines are

straight. Repeat with the other riser, if applicable. Attach

the rest of the connector links to the tension device and

do a thorough continuity check from the canopy to the

connector links. If the lines were incorrectly assembled,

disconnect the link from the riser, remove the lines, and

reinstall them onto the connector link in the correct order.

Reinstall the connector link to the riser. Check the entire

canopy for correct continuity. Make sure the connector

link is tightened properly.

|