Chapter 5

DAMAGE IDENTIFICATION

During the inspection process, the rigger may identify

various discrepancies in the materials and/or the assemblies.

While the following inspection processes call out

what to look for, the specific descriptions and treatment

of the damage are provided in Chapter 7—Repairs,

Alterations, and Manufacture.

PILOT CHUTE AND BRIDLE

1. Check the spring shape and tension; it should not have

an excessive bend to the length of the spring. There

should be no kinks in the wire or sharp edges or burrs.

The swages should be smooth and tight. Check the tension

of the spring against the manufacturer’s specifications.

Most current springs have between 20-30 pounds

of tension, but some run as high as 40-45 pounds. Too

strong a string is rarely an issue, but too weak often is a

problem. Some manufacturers specify a testing method

and frequency of testing.

2. Check the canopy cap for security to the canopy portion

along the stitching and seams. If it has a grommet in

the cap or an alignment strap, check the grommets for

tightness and smooth edges on the inside. Sharp edges

can cut the locking loop. Check the alignment strap for

centering and tacking.

3. Check the canopy fabric for any holes, burns, stains, or

other damage. Check the seams for loose stitching and

look over the mesh portion, if used. Small holes may be

allowed, but consult the manufacturer’s manual. Check

the attachment loop at the base of the pilot chute for security.

Check any hand tacking, if used, to secure the spring

to the base of the pilot chute.

4. If the parachute uses a sewn-on bridle, check the stitching.

If it is a tied-on model, check the knots and any hand

tacking called out in the instructions. Be sure to check the

length against the parts list. Make sure the canopy end of

the bridle is looped around the apex lines and not around

a tension loop. If a floating loop is called out, make sure

the locator tacking is secure.

RESERVE CANOPY

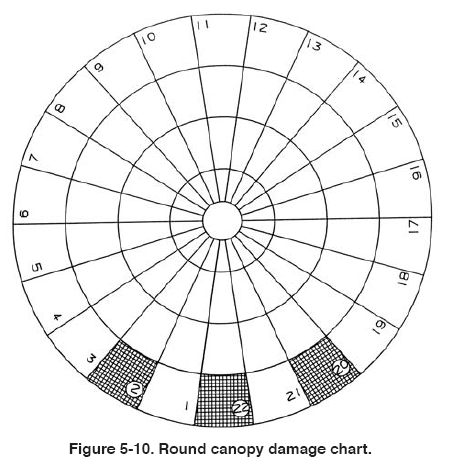

If available, use a canopy damage chart appropriate to

the canopy for documenting your inspection for repair of

any damage found. Figure 5-10 shows a typical chart for

round canopies.

1. Check the apex lines for damage and continuity as well

as the upper lateral band. If there is a tension loop, make

sure it is secure. If there is a vent collar ring, check the

elasticity of the material.

2. Inspect gores and panel fabrics by starting at the top

center gore of the canopy, working your way up one gore

while inspecting the fabric, seams, tapes, and lines. When

you reach the apex, pull the next radial seam toward you,

stretching out the fabric, and work your way down the

gore to the lower lateral band. [Figure 5-11 on page 5-8]

This method is the most efficient use of your time and

physical efforts. Work your way around the canopy,

inspecting each gore from top to bottom.

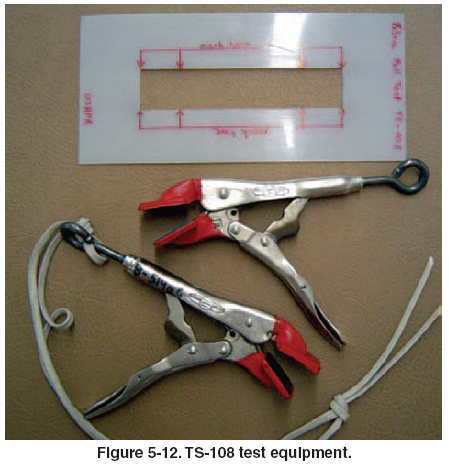

3. The manufacturer may call for the tensile testing of the

fabric after inspection of the canopy for obvious visual

damage. This is very important because there was a fabric

deterioration problem with certain parachutes several

years ago. An AD was issued, and while the exact cause

was never determined, a side benefit was the development

and adoption of a non-destructive fabric pull test method.

This method was adopted by the Parachute Industry

Association (PIA) as Technical Standard TS-108,

Parachute Canopy Fabric Pull Test, Non-Destructive

Method. This method of testing canopy fabric for strength

has been adopted by several canopy manufacturers as

suitable for testing their canopies. However, the rigger

must be careful in using this test method. The proper

equipment is essential for accurate testing and the type of

material must be known in order to test to the correct

strength. The testing equipment is shown in figure 5-12.

The full standard can be found in Appendix I of this handbook.

4. Along with the pull test, the AD also requires testing

the canopy mesh with a solution of Bromo Cresol Green

indicator to determine the presence of an acid condition.

The Bromo Cresol Green indicator is a dark blue liquid

in its standard state. It turns yellow when it contacts

acid—the stronger the acid, the brighter the yellow. If the

test is positive, the canopy will need to be treated to neutralize

the condition. The AD highlights the manufacturer’s

service bulletin as to how to comply with this test

and procedure.

5. If the canopy has a deployment device such as a diaper,

check that it is securely attached, particularly after use.

Check the grommets, line stow bands, elastics, or other

line stow devices. Pay particular attention to where the

stitching attaches to the canopy fabric. This area can be

particularly prone to damage during opening.

|