Chapter 5

SUSPENSION LINES AND CONNECTOR LINKS

1. The lines, their attachment points, and the associated

stitching should be checked for damage or missing

stitches. With the older sheath and core nylon lines such

as Ty-III found on military surplus canopies, the zigzag

stitching at the links are prone to raveling. The more

modern noncontinuous line canopies use Dacron® or

nylon braided lines. The common attachment at the links

for these lines uses the “finger-trap” method to secure the

lines to the link, with a bar tack securing the lines. Most

manufacturers now use a contrasting color thread for the

bar tack in order to make inspection easier. Make sure all

bar tacks are in place. Figure 5-13 shows both methods of

line attachment to the links.

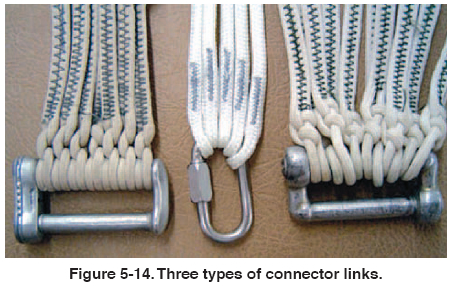

2. There are three basic types of separable connector

links in common use today for round canopies. They are

the standard “L” bar type, MS-22002; the Navy speed link, MS-22021; and the Quick link, commonly called the

Maillon Rapide® link, named after the French company

that first manufactured them. [Figure 5-14] The older military

surplus canopies are usually found with the two

types of MIL-SPEC connector links. Modern sport

canopies usually are found with the Rapide® links

because of their compatibility with the modern low bulk

suspension lines.

3. With the MIL-SPEC links, check the tightness of the

screws that hold the links together. With the speed links,

make sure the knurled side of the end cap is facing up and

the plates face outboard on the riser. The screw should

be checked for tightness at each repack.

4. If the canopy is equipped with Rapide® links, they

should be oriented on the riser with the barrel inboard and

to the bottom so it tightens upward. The link should be

tightened hand tight, then approximately one quarter turn

further. The actual force recommended for a number 5

link is approximately 30 foot-pounds. Most riggers do not

possess the force gauge to measure this, so they use the

quarter turn guide. After tightening the links, a “telltale”

should be applied to the barrel. [Figure 5-15] A telltale is

a marker, usually nail polish, that provides a breakable

seal to show if the barrel has moved. If the seal is broken,

the rigger knows the link may be loose. In doing a repack,

if the telltale is intact, the rigger should not loosen the

link and retighten it because continual tightening can strip

the threads, causing the link to fail.

|