Chapter 5

HARNESS

1. Starting at the riser end, check the webbing for any

wear or damage and inspect the stitching at the riser ends.

If the canopy has steering lines and a guide ring on the

riser, make sure the ring is secure and the steering line is

attached to the steering toggle correctly. With a round

canopy, make sure the steering line has sufficient slack in

it when under tension. If the line is too tight, it can fail at

opening because of too much stretch.

2. Continue down the risers. If canopy releases are

installed, check their operation. With the Capewell cable

release, open the release and make sure there is no dirt or

sand in the mechanism. Also, check for wear, particularly

on the cable ring.

3. Check all of the harness webbing for wear both from

chafing, abrasion, and sunlight degradation. Pay particular

attention to the buffer and chafing strips where used

to prevent wear from the hardware. These buffers are

there to provide early warning before the load bearing

webbing starts to wear. Check the elastic keepers so the

running ends of the straps can be properly stowed.

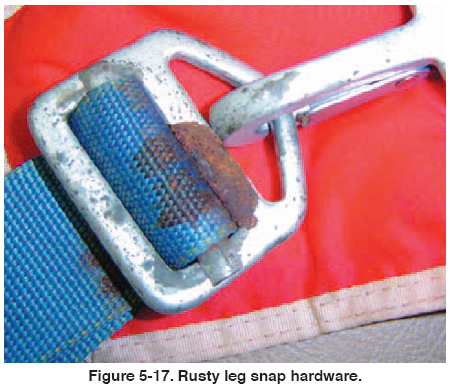

4. Check all of the hardware, paying particular attention

to the leg snaps. Quick ejectors are particularly prone to

failure of the springs. Obviously, those with broken

springs should be replaced. B-12 snaps are prone to having

the gate sides bent to the point they will not close

properly. This gate may be repaired with a screwdriver

and pliers. [Figure 5-16] Straightening the side of the gate

allows the snap to close properly.

5. An area of concern for many riggers, one for which

there is not much guidance, is how much plating wear and

associated corrosion of the hardware is allowable. This

depends on the location of the damage. If it is a solid ring

or buckle, and the damage has occurred from dragging or

abrasion in an area that is not in contact with webbing,

one solution is to clean the rust with a fine emery cloth

and cover it with clear nail polish. This keeps the area

from continued rusting. It will not, however, prevent further

damage caused by the original rusting. If the rusting

is caused by two pieces of hardware interacting with each

other, the problem is more serious. If allowed to continue, the rust pattern may cause the two pieces to fuse together

under the most severe conditions. In this case, the hardware

must be removed and replaced. If the hardware in

contact with webbing, such as a leg strap adapter,

becomes corroded, it must be replaced. This problem frequently

arises when the parachute is exposed to salt water

and not properly rinsed. The hardware will rust inside the

leg strap webbing causing accelerated wear and must definitely

be replaced. [Figure 5-17]

6. The ripcord housing and pocket should be checked for

wear and fit of the ripcord. On the housing, check the ends

and the ferrules. On more modern assemblies, these ferrules

are brass and more susceptible to wear than the MILSPEC

types. Look inside to make sure there are no

obstructions to interfere with the ripcord. The ripcord

pocket may be elastic, VelcroŽ, or a military style with a

spring to hold in the ripcord. Whichever type, make sure

the ripcord is held securely, yet at the same time make sure

it is not too tight so the ripcord can be removed easily.

Also, check the tackings that hold the housing and pocket.

|