|

|

||

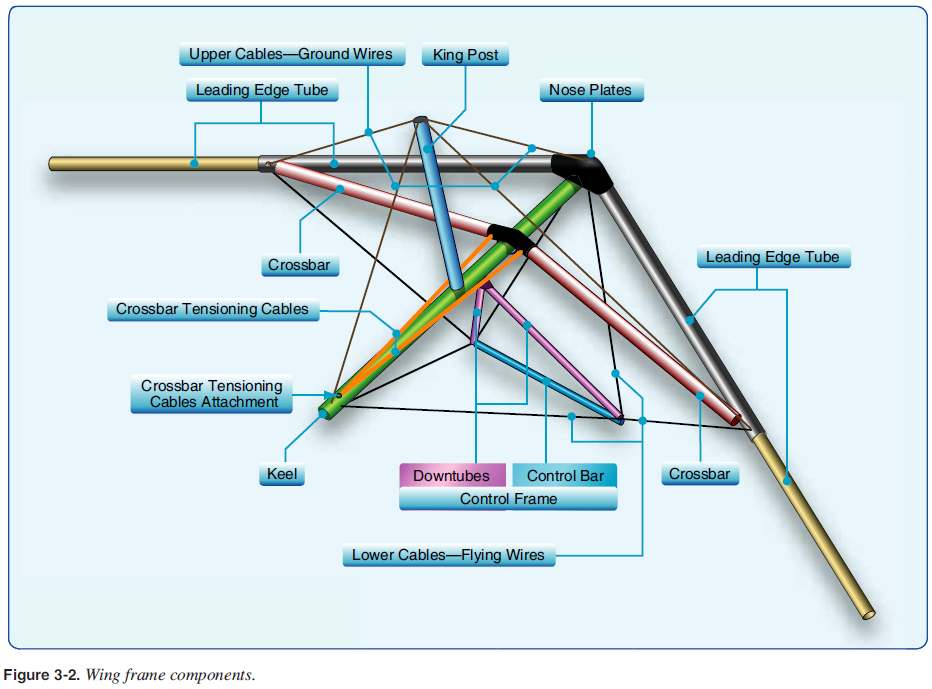

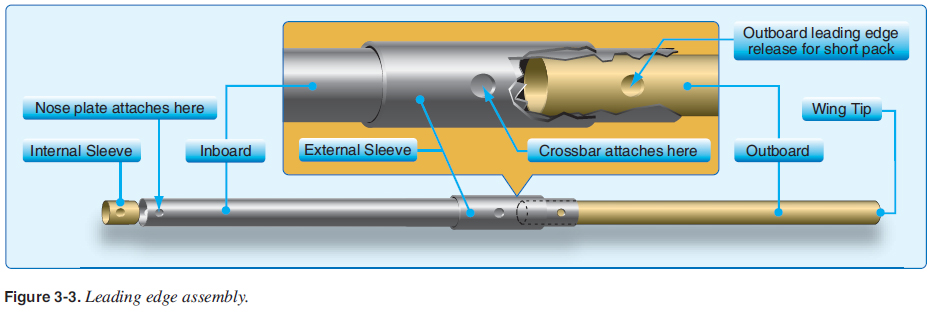

CHAPTER 3. Components and Systems Wing The wing has a structural frame that the sail fits over. Although the wing structure is rigid, it is designed to move and allow the sail to fl ex and the wing to deform or “warp,” to provide a simple control system with no pulleys, push rods, hinges, control cables, or separate control surfaces. This simplifi es maintenance and reduces the cost and weight of the wing. Each wing is built from high quality aircraft parts including alloyed aluminum tubes, stainless steel cables, hardware, and specially designed sail cloth. Wing Frame Components The structural frame of the wing is composed of the leading edges, keel, crossbar, pilot control frame, king post and wires/ struts. The wing frame is a number of structural triangles formed by the wing components. These triangles, braced by wires and struts, provide a strong and lightweight frame to support the fl exible sail. [Figure 3-2]  Leading Edges Leading edges are tube assemblies that are at the front of the wing, the leading edges of the wing airfoil. These are swept back to form the front shape of the wing and attached to each other with nose plates. The leading edges support the airfoil and are designed to fl ex as part of the wing structure. The leading edges are each made up of two main sections, an inboard and an outboard section, as shown in Figures 3-2 and 3-3. Additional tubing “sleeves” are typically used for added strength where the leading edge attaches to the nose plates, and where the inboard and outboard tubes join at the crossbar attachment. This sleeving can be internal or external depending on the specifi c manufacturer’s design. Typically, additional sleeving is used throughout the leading edges at various locations to strengthen and vary the fl ex for the particular design of the wing. Each manufacturer and make/model uses different internal and external sleeving to accomplish specifi c strength and fl ex characteristics. Generally, the inboard sections are stiffer and the outboard leading edge section fl exes as part of the fl exible wing design. Sleeving is commonly added throughout the aircraft where bolt holes are drilled through the tubing to reinforce it around the bolt hole. The outboard leading edge sections can be removed to pack up the wing into a “short pack” which is commonly used for shipping. [Figure 3-3]  |

| ©AvStop Online Magazine Contact Us Return To Books |