|

|

||

| CHAPTER 4. Powerplants

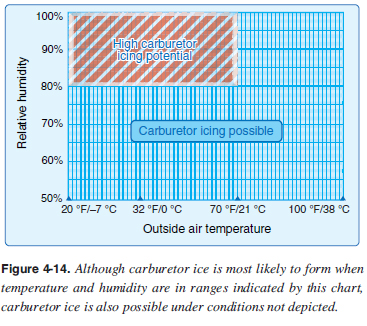

Two-Stroke Carburetor Jetting for Proper Mixture Carburetors are normally set at sea level pressure with the jets and settings determined by the manufacturer. [Figure 4-13] However, as altitude increases, the density of air entering the carburetor decreases, while the density of the fuel remains the same. This creates a progressively richer mixture, same fuel but less air, which can result in engine roughness and an appreciable loss of power. The roughness is usually due to spark plug fouling from excessive carbon buildup on the plugs. Carbon buildup occurs because the excessively rich mixture lowers the temperature inside the cylinder, inhibiting complete combustion of the fuel.  This condition may occur at high elevation airports and during climbs or cruise fl ight at high altitudes. To maintain the correct fuel/oil/air mixture, the main jets are usually changed for smaller jets based on the density altitude of the base airport. Operating from low altitude airports and climbing to altitude where the mixture becomes rich for short periods is acceptable. Operating an aircraft at a lower altitude airport with the jets set for higher altitudes will create too lean of a mixture, heat up the engine, and cause the engine to seize. The pilot must be aware of the jetting for the machine to adjust the mixture. Consult your POH for specifi c procedures for setting jets at different density altitudes. Four-Stroke Mixture Settings Four-stroke engines typically have automatic mixture control for higher altitudes or a mixture control that can be operated by the pilot. Carburetor Icing One disadvantage of the carburetor system versus the fuel injected system is its icing tendency. Carburetor ice occurs due to the effect of fuel vaporization and the decrease in air pressure in the venturi, which causes a sharp temperature drop in the carburetor. If water vapor in the air condenses when the carburetor temperature is at or below freezing, ice may form on internal surfaces of the carburetor, including the throttle valve. Ice generally forms in the vicinity of the venturi throat. This restricts the fl ow of the fuel/air mixture (fuel/oil/air mixture for two stroke) and reduces power. If enough ice builds up, the engine may cease to operate. Carburetor ice is most likely to occur when temperatures are below 70 °F (21 °C) and the relative humidity is above 80 percent. However, due to the sudden cooling that takes place in the carburetor, icing can occur even with temperatures as high as 100 °F (38 °C) and humidity as low as 50 percent. This temperature drop can be as much as 60 to 70 °F. Therefore, at an outside air temperature of 100 °F, a temperature drop of 70 °F results in an air temperature in the carburetor of 30 °F. [Figure 4-14]  The fi rst indication of carburetor icing is a decrease in engine rpm, which may be followed by engine roughness. Although carburetor ice can occur during any phase of fl ight, it is particularly dangerous when using reduced power during a descent. Under certain conditions, carburetor ice could build unnoticed until trying to add power. To combat the effects of carburetor ice, some engines have a carburetor heat option. Some of the newer four-stroke engines have carburetor heat turned on all the time to combat icing. Two-stroke engines are typically less susceptible to icing but specifi c installations dictate how susceptible the carburetor is to icing. Consult the aircraft POH for the probability of carburetor ice for the specifi c installation and for carburetor ice procedures. |

| ©AvStop Online Magazine Contact Us Return To Books |