|

|

||

| CHAPTER 4. Powerplants

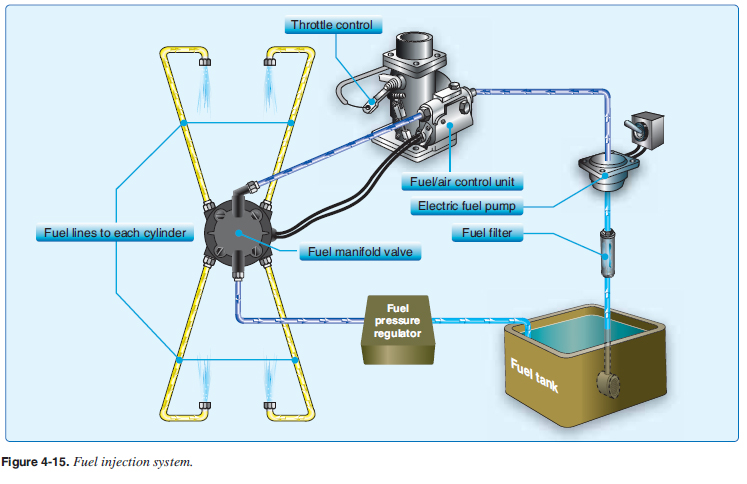

Fuel Injection Induction Systems In a fuel injection system, the fuel is injected either directly into the cylinders or just ahead of the intake valve. A fuel injection system usually incorporates these basic components: engine-driven fuel pump, fuel/air control unit, fuel manifold (fuel distributor), discharge nozzles, auxiliary fuel pump, and fuel pressure/fl ow indicators. [Figure 4-15]  The engine-driven fuel pump provides fuel under pressure from the fuel tank to the fuel/air control unit. This control unit, which essentially replaces the carburetor, meters the fuel and sends it to the fuel manifold valve at a rate controlled by the throttle. After reaching the fuel manifold valve, the fuel is distributed to the individual fuel discharge nozzles. The discharge nozzles, which are located in each cylinder head, inject the fuel/air mixture at the precise time for each cylinder directly into each cylinder intake port. Some of the advantages of fuel injection are:

Disadvantages include:

|

| ŠAvStop Online Magazine Contact Us Return To Books |