|

|

||

| CHAPTER 4. Powerplants

Oil Systems In a four-stroke engine, the engine oil system performs several important functions, including:

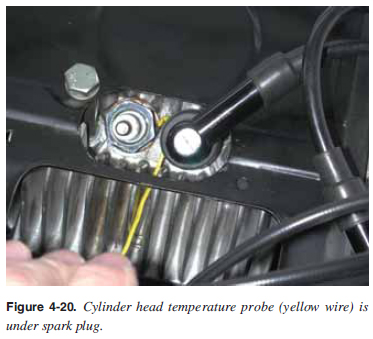

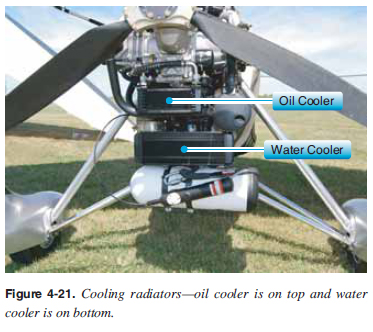

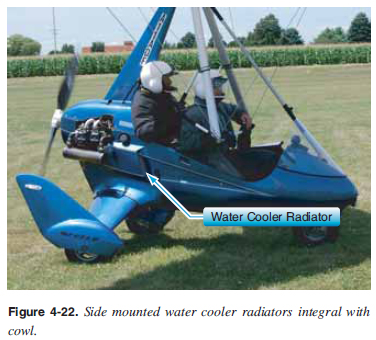

Four-stroke engines use either a wet sump or dry sump oil system. Refer to the Pilotís Handbook of Aeronautical Knowledge for more information on four-stroke oil systems. Engine Cooling Systems The burning fuel within the cylinders produces intense heat, most of which is expelled through the exhaust system. Much of the remaining heat, however, must be removed, or at least dissipated, to prevent the engine from overheating. While the oil system in a four-stroke engine and the fuel-oil mix in a two-stroke engine is vital to the internal cooling of the engine, an additional method of cooling is necessary for the engineís external surface. WSC engines operate with either air-cooled or liquid-cooled systems. Many WSC aircraft are equipped with a cylinder head temperature (CHT) gauge. This instrument indicates a direct and immediate cylinder temperature change. This instrument is calibrated in degrees Celsius or Fahrenheit. Proper CHT ranges can be found in the POH/AFM/AOI for that machine. [Figure 4-20]  Air cooling is accomplished by air being pulled into the engine shroud by a cooling fan. Baffl es route this air over fi ns attached to the engine cylinders where the air absorbs the engine heat. Expulsion of the hot air takes place through one or more openings in the shroud. If cylinder head temperatures rise too much in an air-cooled engine, it is because of lubrication problems, cooling fan drive belt damage or wear, Liquid cooling systems pump coolant through jackets in the cylinders and head. The heated liquid is then routed to a radiator where the heat is radiated to the atmosphere. The cooled liquid is then returned to the engine. If the radiator is mounted close to the propeller, the propeller can constantly move air across the radiator and keep the engine cool even when the WSC is not moving. [Figure 4-21] Radiators mounted away from the propeller make it more diffi cult for the radiator to cool the engine unless the WSC is moving. [Figure 4-22]   Breaking in an engine through ground runs on a hot day is when radiator placement is most critical. Liquid-cooled engines can overheat for a number of reasons, such as coolant not at proper levels, a leak, failed water pump, or a blockage of the radiator. Operating an engine above its maximum design temperature can cause a loss of power and detonation. It will also lead to serious permanent damage, such as scoring the cylinder walls and damaging the pistons and rings. Monitor the engine temperature instruments to avoid high operating temperature. Operating the engine lower than its designed temperature range can cause piston seizure and scarring on the cylinder walls. This happens most often in liquid-cooled WSC aircraft in cold weather where large radiators designed for summer fl ying may need to be partially blocked off. |

| ©AvStop Online Magazine Contact Us Return To Books |