|

|

||

| CHAPTER 4. Powerplants

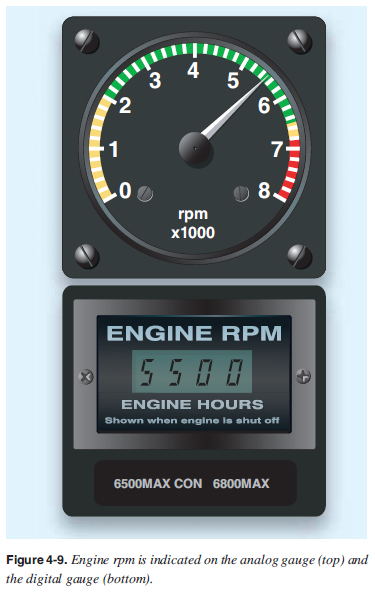

Four-Stroke Engine Warming A four-stroke engine must also be warmed up. The fourstroke engine has a pressurized oil system that provides more uniform engine temperatures to all of its components. Takeoff power can be applied as soon as the water, cylinder head temperature (CHT), oil temperatures, and oil pressure are within the manufacturer’s recommended tolerances for takeoff power applications. Gearboxes Gearboxes are used on most WSC reciprocating engines to take the rotational output of an internal combustion engine which is turning at a high rpm and convert it to a slower (and more useful) rpm to turn the propeller. Gearboxes come in different gear ratios depending on the output speed of the engine and the needed propeller turning speeds. Some examples are a two-stroke rpm reduction from 6,500 engine rpm with a 3.47 to 1 reduction, resulting in 1,873 propeller rpm. A four-stroke rpm reduction could be from 5,500 engine rpm with a 2.43 to 1 reduction, resulting in 2,263 propeller rpm. A gearbox is a simple device that bolts directly to the engine and, in turn, has the propeller bolted directly to it. A two-cycle engine gearbox is kept lubricated with its own built-in reservoir of heavy gearbox oil. The reservoir is actually part of the gearbox case itself. The gearbox oil has to be changed periodically since the meshing of the gears will cause them to wear and will deposit steel fi lings into the oil. If the oil is not changed, the abrasive fi lings cause even more wear. Some gearboxes have a built-in electric starter motor. When activated, the motor turns the gearing which cranks the engine. Four-stroke propeller reduction gearboxes use oil from the engine oil system for lubrication. Some gearboxes come with a built-in centrifugal clutch and others have allowances for installation. A centrifugal clutch is very useful in a two-stroke engine because it allows the engine to idle at a lower speed without the load of the propeller. Otherwise, two-stroke engines can generate a great deal of vibration at low rpm when loaded. As the engine speeds up, the centrifugal clutch engages and smoothly starts the propeller spinning. When the engine is brought back to idle, the clutch disengages and allows the engine to idle smoothly again; the propeller stops when on the ground and windmills when fl ying. Propeller The propeller provides the necessary thrust to push the WSC aircraft through the air. The engine power is used to rotate the propeller, which generates thrust very similar to the manner in which a wing produces lift. The amount of thrust produced depends on the airfoil shape, the propeller blade angle of attack (AOA), and the engine rpm. [Figure 4-9] Light-sport aircraft (LSA) are equipped with either a fi xed-pitch or a ground adjustable-pitch propeller.  Fixed-Pitch Propeller The pitch of the fixed-pitch propeller is set by the manufacturer and cannot be changed. Refer to the Pilot’s Handbook of Aeronautical Knowledge for basic propeller principles. |

| ©AvStop Online Magazine Contact Us Return To Books |