|

|

||

| CHAPTER 5. Prefl ight and Ground Operations

Flight Deck Management After entering the fl ight deck, the pilot should fi rst ensure that all necessary equipment, documents, checklists, and navigation charts appropriate for the fl ight are on board. [Figure 5-63] If a portable intercom, headsets, or a hand-held global positioning system (GPS) is used, the pilot is responsible for ensuring that the routing of wires and cables does not interfere with the motion or the operation of any control.  Regardless of what materials are to be used, they should be neatly arranged and organized in a manner that makes them readily available. The fl ight deck should be checked for articles that might be tossed about if turbulence is encountered, and any loose items properly secured. When the pilot is comfortably seated, the safety belt and shoulder harness (if installed) should be fastened and adjusted to a comfortably snug fi t. The safety belt must be worn at all times the pilot is seated at the controls. Checklist After Entering Flight Deck

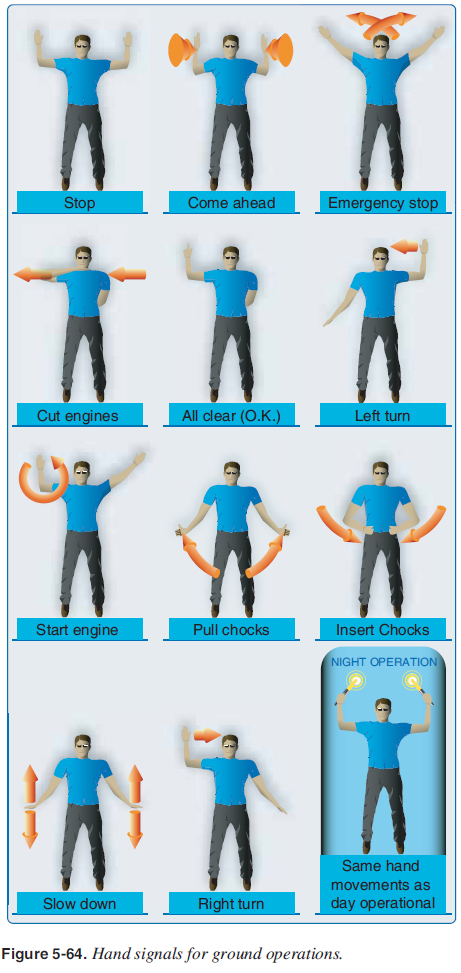

It is important that a pilot operates an aircraft safely on the ground. This includes being familiar with standard hand signals that are used universally for ground operations. [Figure 5-64]  Engine Start The specifi c procedures for engine start vary greatly since there are as many different methods as there are engines, fuel systems, and starting conditions. The engine start checklist procedures in the POH should be followed. The following are some basic steps that apply to most aircraft:

A relatively low rpm setting is recommended immediately following engine start. This is typically a slight increase in the throttle to keep the engine running smoothly. It is not recommended to allow the rpm to race immediately after a start with a cold engine, as there is insuffi cient lubrication until the oil pressure rises on four-stroke engines, and unequal heating on two-stroke engines. In freezing temperatures, the engine is also exposed to potential mechanical distress until it warms and normal internal operating clearances are reached. On four-stroke engines, as soon as the engine is started, the oil pressure should be checked. If it does not rise to the manufacturer’s specifi ed value, the engine may not be receiving proper lubrication and should be shut down immediately to prevent serious damage. |

| ©AvStop Online Magazine Contact Us Return To Books |