Chapter 3. ANTENNA INSTALLATIONS

| 36. PERFORMANCE.

For proper performance, it is important that the radio equipment manufacturer's

instructions be carefully followed in matching and coupling the antenna

to the radio equipment.

a. The location of the antenna is of primary importance. When selecting

a mounting position, consideration should be given but not limited to the

following:

(1) Obstruction to signal reception by aircraft or aircraft

components.

(2) Ignition noise (RF radiation pickup).

(3) Vibration.

(4) Flutter.

(5) Instrument static source interference. |

|

b. Attach antenna mounting (masts, base receptacles, and/or supporting

brackets) so that the loads imposed (for example, air, ice, etc.) are transmitted

to the aircraft structure.

37. VHF ANTENNA - WHIP.

a. Locate this type antenna so that there is a minimum of structure

between it and the ground radio stations. The antenna may be mounted on

the top or bottom of the fuselage. It is not advisable to mount the antenna

on the cowl forward of the windshield because a lightning strike might

possibly blind the pilot.

b. Methods of securing whip antennas to the structure are shown in figures

3.1

and 3.3.

c. On fabric covered aircraft or aircraft with other types of nonmetallic

skin, the manufacturer's recommendations should be followed in order to

provide the necessary ground plane. An acceptable method of accomplishing

this is by providing a number of metal foil strips in a radial position

from the antenna base and secured under the fabric or wood skin of the

aircraft. (See figure 3.2)

38. VHF ANTENNA - RIGID.

a. When it is necessary to cover a broader frequency range than can

be covered by a whip antenna, a blade type should be used because it is

resonant over a much broader frequency range. However, a broadband antenna

is not as efficient as a small diameter whip antenna and, accordingly,

should not be used with relatively low output transmitters (under 5 watts).

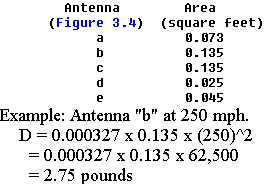

(1) The antennas shown in figure 3.4 are normally

installed at a point on the fuselage directly above the cabin or baggage

compartment.

When a rigid antenna is installed on the vertical stabilizer, evaluate

the flutter and vibration characteristics of the installation.

(2) The approximate drag load an antenna is required to withstand can

be determined by the following formula:

D = 0.000327 x A x V^2

(The formula includes a 90 percent reduction factor for streamline shape

of antenna.)

Where D is the drag load on the antenna in pounds,

A is the frontal area of the antenna in square feet, and

V is the Vne of the aircraft in mph.

The frontal area of typical antennas are approximately as follows:

b. Installation of Rigid Antennas.

(1) Place a template similar to figure 3.5 on

the fore-and-aft centerline at the desired location. Drill the mounting

holes and the correct diameter hole for the transmission line cable in

the fuselage skin.

(2) Install a reinforcing doubler of sufficient thickness to reinforce

the aircraft skin. The length and width of the plate should approximate

that illustrated in figures 3.6 or 3.8.

(3) Install antenna on fuselage, making sure that the mounting bolts

are tightened firmly against the reinforcing doubler, and that the mast

is drawn tight against the gasket.

When a gasket is not used, seal the crack between the mast and fuselage

with a sealer, such as zinc chromate paste or equivalent.

(4) Route transmission line cable to the receiver, secure the cable

firmly along its entire length at intervals of approximately 2 feet, and

take care to prevent fouling of control cables.

39. VHF NAVIGATION RECEIVING ANTENNAS.

Locate antennas for omnirange (VOR), and instrument landing system (ILS)

localizer receivers at a position on the aircraft where they will have

the greatest sensitivity for the desired signals and minimum response to

undesired signals such as electrical energy radiated by the engine ignition

system. A good location for the VOR localizer receiving antenna on many

small

airplanes is over the forward part of the cabin. Mount the rigid V-type

antenna so that the apex of the "V" points forward and the plane of the

"V" is level in normal flight. {See Figure 3.7.}

a. VOR Antenna Balun and Transmission Lines.

A dual element or balanced antenna system requires a balun or an impedance

matching device for maximum signal transfer into an unbalanced coaxial

cable. Rigid antennas, as displayed in figure 3.4,

incorporate a balun as an integral component of the antenna assembly. Follow

the manufacturer's installation procedures and assure that the balun is

properly grounded to the airframe. Refer to AC 43.13-1A "Acceptable Methods,

Techniques, and Practices - Aircraft Inspection and Repair" chapter 11,

for acceptable bonding practices. {See Figure 3.9.}

(1) {(2) in original - Ed.} Figure 3.10 is an

illustration of a typical VOR antenna balun. A balun made from a section

of the transmission line functions as a tuned circuit or transformer which

produces a standing wave ratio to provide the desired matching impedance.

When the antenna is matched to the line, the line measurement in multiples

of wave lengths is not critical.

(2) Radio wave velocity is less in a cable than in air; therefore, the

wave length in cable will be shorter than in air. Appropriate test equipment

must be used for transmission line measurements because the physical and

electrical lengths of lines are not always equal.

(3) The transmission line should be kept as short as possible. Any bends

in the cable should have at least a 3 inch radius. Follow the equipment

manufacturer's recommendations regarding transmission lines and lengths.

b. Assembly of Coaxial Cable Connectors.

Optimum performance of a radio system is dependent upon the coaxial

cable connector assembly. Follow the manufacturer's assembly instructions.

Assure that the cable is not distorted or flattened when cutting. The electrical

characteristics of the cable change when flattened or bent sharply.

(1) To remove the outer jacket, cut with a sharp knife around the circumference,

then make a lengthwise slit and peel off the outer jacket. Do not nick,

cut or damage the shield.

(2) Comb out the braid and bend back to expose the dielectric. Use a

sharp knife to cut the dielectric around the circumference, not quite through

to the center conductor. Do not nick or cut the conductor. Remove the dielectric

by twisting and pulling. {See Figure 3.11.}

(3) Solder the contact to the center conductor. Use a clean, well-tinned

soldering iron. {See Figure 3.12.}

(4) Do not apply heat too long as this will swell the dielectric and

make it difficult to insert into the body of the connector.

{See Figure 3.13.}

(5) Install connector body and tighten until secure. Do not over tighten

as this will distort the cable. {See Figure 3.14.}

(6) Use only the crimping tool recommended by the manufacturer, or an

equivalent tool when installing connectors which utilize a crimp-type contact.

c. Dual VOR/NAV Receiver Installations.

Two VOR navigation receivers can be connected to a common VOR antenna.

This is accomplished by utilizing a coaxial tee connecter (UG-274 A/U)

and matched 0.5 wavelength coaxial cable lengths connected from the tee

connector to the respective VOR receivers. Typical cable lengths are from

22 to 35 inches and multiples of these lengths. Another method of coupling

two VOR navigation receivers to a common antenna is by utilizing a device

called a coupler or diplexer. This device,

in addition to impedance matching, also provides isolation between

VOR navigation receivers while keeping line insertion losses at a minimum.

40. RANGE RECEIVING ANTENNAS.

Mount "T", "L", or "V" antennas on top or bottom of the aircraft with

approximately 1 foot clearance from the fuselage and wings. Typical wire

antenna installations are shown in figures 3.15

through 3.19. {See Figure 3.16}

{See Figure 3.17} {See Figure 3.18}

41. MARKER RECEIVING ANTENNA.

The marker receiver operates at a frequency of 75 MHz. In order to keep

to a minimum the number of antennas on the aircraft, the marker receiver

may utilize the same antenna as the range receiver if that antenna is mounted

on the underside of the aircraft. However, both receivers should include

provisions to permit simultaneous operation without interference. A whip

or other vertical type of antenna should not be used for marker reception

since the ground facility transmits from a horizontally polarized antenna.

42. ATC RADAR BEACON (TRANSPONDER) AND DISTANCE MEASURING EQUIPMENT

(DME) ANTENNAS.

Locate these antennas at an unobstructed location on the underside of

the fuselage, preferably at the lowest point of the aircraft when in level

flight. To the extent practicable, mount the antenna so that the base is

horizontal when the aircraft is in cruise attitude.

a. Installation.

Mount the antennas at least 36 inches away from obstructions and as

far as possible from other antennas. Tests have shown that the location

of the antenna with respect to obstructions is of greater importance than

having the antenna installed in a vertical position. However, signal strength

and pattern become noticeably affected as the angle of the antenna approaches

45° from the desired vertical position. On fabric covered aircraft

or aircraft with other types of nonmetallic skin, it will be necessary

to provide a flat metallic surface or "ground plane" extending at least

12 inches in all directions from the center of the antenna. Be sure the

antenna makes a good, direct electrical connection with the ground plane.

Install gaskets, pressurization seals, and/or sealant as required. {See

Figure 3.19.} {See Figure 3.20.}

b. Dual System Installations.

When dual ATC radar systems, dual DME systems, or combinations of these

systems are installed, determine that the separation between their respective

antennas is within the manufacturers prescribed limits. (See paragraph

2-7i for mutual interference in DME and ATC radar beacon systems.)

c. Antenna Cable.

Route the antenna cable in the most direct path practicable. Since losses

can be relatively high at these frequencies, follow the equipment manufacturer's

recommendations regarding transmission lines and lengths.

43. DIRECTION FINDING ANTENNAS (100 to 1750 KHz).

Manual or automatic loop-type antennas are used with direction finding

receivers. The loops are designed for use with a particular receiver. Connecting

wires between the loops and receivers are also designed for the specific

equipment. Accordingly, only components meeting the specification characteristics

of the receiver manufacturer should be used.

a. Loops enclosed in streamlined housings or exposed loops are satisfactory

for external mounting on an aircraft. Loops may also be flush mounted on

the aircraft when proper attention is given to avoid interference from

metallic structure and skin of the aircraft. {See Figure 3.21.}

b. Sense antennas are used to resolve radio bearing ambiguity in direction

finding systems. The sense and its leadin must be matched to the input

capacitance of the ADF receiver. The sense antenna capacitance is a function

of length, spacing between antenna and fuselage, and leadin capacitance.

To achieve this antenna/receiver capacitance match, it is important that

the sense antenna be installed in accordance with the ADF manufacturer's

recommendations for the particular make and model of aircraft.

c. Installation kits are designed for either top or bottom fuselage

mounting of loop and sense antennas, or a combination of these two locations.

Particular attention should be paid to the manufacturer's installation

instructions for antenna location (top or bottom) and loop output connections,

in order to prevent 180° errors in bearing indications.

d. Optimum ADF performance, is achieved when the "T", rather than the

"L", type of sense antenna is used, (see figure 3.15).

The "T" type has a noise canceling effect due to the antenna cable being

connected in the center of the antenna. The "L" type antenna has directional

characteristics and may not produce a definite station passage indication

as the "T" type does. A whip antenna of a type and dimension recommended

by the equipment manufacturer may be used in place of the "T" or "L" types.

Methods of installing a whip antenna are shown in figures 3.1,

3.2,

and 3.3.

e. Because the ADF receiver is susceptible to aircraft radiated noise,

antenna leadins should be routed so that they are kept away from electric

power cables, alternators, solid state power supplies, anticollision lights,

pulse transmitting equipment, etc. They may be routed against airframe

members for extra shielding.

f. Loopins should be of the recommended type and length. The length

of leadin specified by the manufacturer for a particular installation may

be excessive for the physical dimensions between the antenna and receiver.

Excessive leadin should not be trimmed, but should be coiled to take up

the extra length. Do not coil excess cable in any area subject to electrical

noise.

g. After completing the installation, it is essential that the loop

be calibrated. One acceptable means of compliance is contained in AC 43.13-1A.

chapter 15, section 6, paragraphs 848 through 853.

44. ANTENNA INSTALLATION ON PRESSURIZED AIRCRAFT.

The use of doublers, to reinforce the aircraft skin to support antennas,

is previously described in this chapter. The material contained in this

paragraph concerns the methods of applying sealant to guard against the

passage of air, liquids, and vapors from pressurized structures.

a. Typical Antenna Installation Procedure.

When the attaching parts and the antenna are ready for installation,

clean all faying surfaces with a cleaning solvent. Clean a larger area

than that to which sealant is to be applied. Remove the solvent from the

faying surfaces by blasting with dry air and wiping with a clean soft cloth.

(1) Coat the affected area with the primer specified by the sealant

manufacturer.

(2) Apply the sealant to one surface, using a spatula or brush, and

spread it over the entire faying surface until a uniform thickness of approximately

1/32 inch is obtained. (See figure 3.22 and 3.23.)

(3) Place the component parts together and install the required fasteners.

If permanent fasteners cannot be installed, use temporary fasteners to

hold the component parts together until the sealant has cured. Install

permanent fasteners with fresh sealant by dipping the fastener in sealant

or by filling the fastener hole with sealant. (See figure 3.24.

(4) Fill holes and joggles by injecting the sealant into the voids and/or

cavities. This method is used where the sealant cannot be applied with

a spatula or brush. Figure 3.25.

(5) Allow the sealant to cure, then remove excess sealant from the periphery

of the antenna using a nonmetallic scraper.

Warning

Sealants may contain toxic, and/or flammable components. Avoid inhalation

of vapors. Supply adequate ventilation and provide a suitable exhaust system.

Wear approved respiratory protection while using these materials in confined

areas. Do not allow the sealant to come in contact with the skin or eyes.

Insure that no source of ignition is present in the working area.

b. High Speed Aircraft.

The sealant methods described should be used to prevent moisture or

water from entering the aircraft and the expulsion of air and vapors when

the aircraft structure is pressurized.

(1) Figure 3.26 displays a blade type antenna

mounted on a flat surface using a sealing gasket. This type of installation

does not require the application of a sealant.

(2) Figures 3.27 and 3.28

display two types of flush mounted antennas. The antenna unit and fiberglass

cover are manufactured as one integral assembly.

(3) Flush mounted antennas installed on a vertical fin are normally

part of the primary structure. The radiating elements of the antenna and

the fiberglass cover are individual units.

(a) Clean all metal surfaces necessary to insure good electrical bonding

contact between the antenna mounting surface and the aircraft structure.

(b) After the fiberglass cover is installed, sealer may be applied to

fill the space between the fiberglass cover and skin of the vertical fin.

Figure 3.29 displays one-half of a vertical fin

antenna installation. An identical installation is required on each side.

45. - 50. [RESERVED]