|

|||||||||||

|

|

|

|||

|

|

||||

|

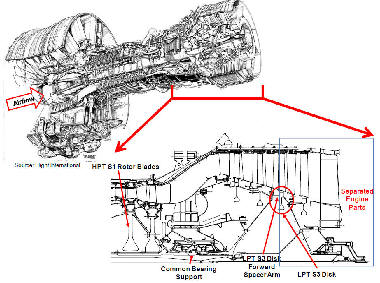

May 28, 2010 — The National Transportation Safety Board (NTSB) has identified a critical safety issue with General Electric Company (GE) CF6-45/-50 series turbofan engine low pressure turbine (LPT) stage 3 (S3) disks that requires immediate action. The investigations of several recent uncontained LPT S3 disk failures have determined that the CF6-45/-50 engine LPT S3 disk, a critical, life-limited rotating engine part, can fail unexpectedly when excited by high pressure (HP) rotor unbalance vibration resulting from localized high pressure turbine (HPT) blade material loss.

|

|||

|

|

||||

|

On July 4, 2008, a

Saudi Arabian Airlines (Saudia) Boeing 747-300 experienced an

uncontained failure of its GE CF6-50 No. 1 engine, during initial climb

after takeoff from

According to the

captain, the fluctuations continued during the initial climb, and, about

1 minute later, at about 1,100 feet above ground level (agl), the

engine’s low oil pressure warning illuminated, and the oil quantity

indicator read zero. The flight crew shut down the engine, dumped fuel,

returned to the airport, and accomplished an uneventful landing. |

||||

|

Postflight

inspection of the airplane found that the aft end of the No. 1 engine

was missing and that airplane damage, including penetration of the

airplane’s left wing and flaps, was consistent with impact from parts

exiting the engine. Examination of the No. 1 engine found that the

engine’s LPT S3 disk had separated at the forward spacer arm and that

all components aft of the separation were missing. Most of the missing

engine components were recovered about 2 1/2 miles from the departure

end of the runway.

The forward and

aft portions of the LPT S3 disk were examined. The disk had separated at

the fillet radius between the forward spacer arm and the rim forward

face. Metallurgical examination of undamaged areas of the disk fracture

surfaces found fatigue cracks initiating around the inner diameter of

the spacer arm from sites spaced about 0.1 inch to 0.2 inch apart.

The cracks had

propagated rapidly through the spacer arm thickness and exhibited

high-stress, high-cycle fatigue, termed high-amplitude fatigue (HAF),

consistent with a high-amplitude per-revolution stimulus. The cracks

joined to form a single circumferential crack, which led to the 360°

fracture and disk separation.

A postincident

video borescope inspection (BSI)5 of the engine’s HPT revealed that

three HPT stage one (S1) blades over a nine-blade sector were missing

airfoil material equivalent to about 1.8 blades. This amount of

localized blade material loss can result in a significant increase in

the eccentricity of the rotor mass center relative to its axis of

rotation (rotor unbalance).

On March 26, 2009,

an Arrow Cargo McDonnell Douglas DC-10F experienced an uncontained

failure of its No. 2 GE CF6-50 engine. There were no injuries. The

airplane was operating under the provisions of 14 Code of Federal

Regulations Part 121 as a regularly scheduled cargo flight from

According to

flight crew reports and flight data recorder information, about 30

minutes after takeoff, about 8,000 feet agl, the airplane’s No. 2 engine

began to lose oil pressure and N1 decreased. The pilots shut down the

engine and diverted to

Postflight

inspection found that the aft end of the No. 2 engine was missing and

that there was impact and tearing damage to the airplane’s horizontal

stabilizers, tail strut, elevator, and rudder. A teardown examination of

the Arrow Cargo engine found that the LPT S3 disk had fractured 360° at

the fillet radius between the forward spacer arm and the rim forward

face and that all components aft of the LPT S3 nozzles were missing. The

liberated engine parts impacted a densely populated area, and 22 homes

were reported damaged.

Metallurgical

examination of the LPT S3 disk fracture surfaces revealed HAF cracks

over approximately 90 percent of the fracture, consistent with a

high-amplitude per-revolution stimulus. The remaining 10 percent of the

fracture showed overstress features. Cracks propagated from initiation

sites spaced about 0.1 inch to 0.2 inch around the inner circumference

of the spacer arm and joined to form a single circumferential crack,

leading to disk separation. Inspection of the HPT rotor found that one

HPT S1 blade was missing about 85 percent of its airfoil.

On December 17,

2009, a Jett8 Cargo Boeing 747-200F airplane, registration 9V-JEB,

experienced an uncontained failure of its No. 4 CF6-50 engine in

Noting rapidly

decreasing No. 4 engine oil pressure and N1, the crew performed the

engine failure checklist and returned to land the airplane at

Post-event

inspection found that the aft end of the No. 4 engine was missing and

that the lower right wing/pylon, the aft right cargo door, and the

vertical stabilizer exhibited damage consistent with impact from

high-energy parts. An inspection of the No. 4 engine found that the

engine’s LPT S3 disk had separated at the forward spacer arm and that

all components aft of the separation were missing. In addition,

localized HPT blade deterioration was observed in a video of a BSI

provided by the Air Accident Investigation Bureau of Singapore. The NTSB

is participating in this investigation.

On April 10, 2010,

an ACT Cargo Airbus A300B4 experienced an uncontained failure of its No.

2 CF6-50 engine while accelerating for takeoff at

The NTSB is

coordinating teardowns and inspections of the Jett8 Cargo and the ACT

Cargo engines in order to gain more insight into the failures.

HPT rotor blades

are expected to deteriorate (lose blade airfoil material) between

overhaul intervals due to the operating stresses they experience. The

blade material loss is usually symmetrical and does not significantly

affect rotor balance. However, when the blade material loss is

localized, detrimental rotor unbalance will occur, resulting in

synchronous, per-revolution vibration.

According to GE,

when sufficient HP rotor unbalance occurs in the CF6-45/-50 engine, the

resulting synchronous vibration forces can interact with the low

pressure (LP) rotor system through a common bearing support and excite a

bladed-disk mode response8 in the LPT S3 disk.

The resonant

frequency experienced by the LPT S3 disk in this mode will result in

forward spacer arm bending loads that exceed the fatigue limit of the

material, which then causes HAF cracks to initiate. The individual

cracks can link together, forming a circumferential crack that results

in separation of the aft section of the LP rotor. The separated rotor

section will penetrate the engine case, releasing high-energy debris.

The structural failure of the engine case will result in the liberation

of all case-supported components aft of the fracture.

The CF6 LPT S3

disk resonance response to HP rotor unbalance was first identified in

the GE CF6-6 engine, which shares the CF6-45/-50 type certificate. The

CF6-6 experienced four uncontained LPT S3 disk forward spacer arm

separations between 1975 and 1978 due to HP rotor unbalance.

As a result, GE

redesigned the CF6-6 LPT S3 disk so that an HP rotor unbalance condition

would not excite the LPT S3 disk and result in disk failure. The CF6-50

engine has experienced 12 instances of LPT S3 disk forward spacer arm

cracking since 1973. Eight of the cracked CF6-50 disk forward spacer

arms were discovered during shop-level inspections when LPTs were

disassembled for unrelated reasons, such as engine model conversion or

the replacement of life-limited parts. In the remaining cases, all of

which are cited above, disk cracks progressed to failure, leading to

in-service uncontained engine failures.

Airplane

maintenance manuals (AMMs) require inspection of CF6-45/-50 HP rotor

blades every 450 flight cycles as part of the engine hot section BSI.

However, the Saudia LPT S3 disk failure occurred about 216 flight cycles

after the engine’s last hot section BSI, and the Arrow Cargo LPT S3 disk

failure occurred about 350 flight cycles after the engine’s last hot

section BSI,10 indicating that a 450 cycle hot section BSI interval was

not adequate to detect HPT blade deterioration that can result in

catastrophic LPT S3 disk failure.

On August 28,

2009, GE issued CF6-45/-50 SB 1307, which recommended that operators of

CF6-45/-50-powered airplanes conduct an HPT rotor blade BSI every 200 or

fewer flight cycles to detect HPT rotor blade material loss earlier,

thus potentially preventing unbalance conditions from occurring.

The Jett8 Cargo

LPT S3 disk failure in December 2009 occurred about 185 flight cycles

after the engine’s last hot section BSI. On March 17, 2010, the FAA

issued immediate Airworthiness Directive (AD) 2010-06-15, effective

April 1, 2010, which requires that CF6-45/-50 HPT rotor blades be

subjected to a BSI for excessive HPT rotor blade material loss or damage

within 50 flight cycles, repetitive BSIs every 175 flight cycles, and,

if excessive HPT blade material loss is found, a fluorescent penetrant

inspection (FPI)11 of the LPT S3 disk before further flight.

However, the most

recent event, which occurred on April 10, 2010, suggests that the

current interim measures are not adequate to prevent uncontained

CF6-45/-50 LPT S3 disk separations. A review of airplane records

indicated that the ACT Cargo engine had been maintained in accordance

with GE SB 1307 since November 2009.

In addition, the

records indicated that an HPT BSI was performed fewer than 50 flight

cycles before the LPT S3 disk failure and that no HPT blade material

loss was noted. On May 10, 2010, GE issued revision 1 of SB 1307, which

recommends an HPT BSI every 75 flight cycles or, if the operator adopts

and maintains additional repetitive maintenance and inspection criteria,

every 350 flight cycles.

The NTSB concludes

that the current CF6-45/-50 engine HPT rotor blade BSI interval is not

adequate and must be further reduced to detect HPT blade material loss

before an HPT unbalance condition can result in an uncontained LPT S3

disk failure. The NTSB believes that BSIs must be performed at an

interval such that if undetectable blade loss begins and continues to

progress, there is still time to potentially identify the HPT blade loss

at the next BSI before an uncontained event is a possibility.

Therefore, because

of the potential for catastrophic damage to the airplane and passengers

from an uncontained engine failure, the NTSB recommends that the FAA

immediately require operators of CF6-45/-50-powered airplanes to perform

HPT rotor blade BSIs every 15 flight cycles until the LPT S3 disk is

replaced with a redesigned disk that can withstand the unbalance

vibration forces from the HP rotor.

The CF6-45/-50

engine manual requires an FPI of the LPT S3 disk whenever the disk is

exposed during rotor disassembly. However, the LPT rotor is not

disassembled during every engine shop visit. Since December 2008, the

CF6-45/-50 engine manual has required an LPT S3 disk FPI to detect HAF

cracks at the forward spacer arm that may have resulted from vibration

forces, if the reason for engine removal includes a report of excessive

HP rotor vibration.

However, HP rotor

vibration was not reported in the 12 instances where LPT S3 disk HAF

cracks were identified either in shop-level inspections or in the

uncontained LPT S3 disk failures. Thus, it is unlikely that vibration

would be reported in other cases of HPT unbalance that would lead to an

LPT S3 disk failure. In addition, GE recently revised the CF6-45/-50

engine manual LPT S3 disk rejection criteria and disk cleaning

requirements to improve the detectability of HAF cracks on the forward

spacer arm.

As a result, some

in-service LPT S3 disks have not been inspected in accordance with this

improved inspection criteria. The NTSB concludes that there may be LPT

S3 disks in service that were exposed to HP rotor unbalance conditions

but not inspected to the latest engine manual standards and that, as a

result, these disks may have accumulated forward spacer arm HAF damage,

making them more susceptible to HPT rotor unbalance. Therefore, the NTSB

recommends that the FAA require operators of CF6-45/-50-powered

airplanes to perform FPI inspections of CF6-45/-50 LPT S3 disks at every

engine shop visit until the LPT S3 disk is replaced with a redesigned

disk that can withstand the unbalance vibration forces from the HP

rotor.

Uncontained

turbine engine disk failures present a direct hazard to the airplane and

its passengers because high-energy disk fragments can penetrate the

cabin or fuel tanks, damage flight control surfaces, or sever flammable

fluid or hydraulic lines. Engine cases are not designed to contain

failed turbine disks. Instead, the risk of uncontained disk failure is

mitigated by designating disks as safety-critical parts.

The design process

for a safety-critical turbine disk includes consideration of the disk’s

critical frequencies and mode shape information so that the part is

designed with an adequate margin of safety. In the case of the LPT S3

disk, an adequate margin of safety should have existed between the

disk’s natural response frequencies and the engine’s operating

frequencies, including the frequencies that result from common fault

conditions, such as HP rotor unbalance.

Further, an engine

vibration monitoring (EVM) system13 can be used to alert flight crews of

impending part failure to increase the margin of safety. However, when

the CF6-45/-50 engine was being certified, the EVM systems installed on

the airplanes that the CF6-45/-50 engines were designed to power were

considered marginal in their ability to detect HP rotor unbalance.

As a result, the

FAA placed a special condition (No. 33-36-EA-9, dated November 8, 1971)

on the CF6-45/-50 type certificate that required GE to show that “the

engine would operate without inducing detrimental stresses in any engine

part while operating with an increased vibration level, such as that

which might result from one or more broken or missing rotor blades, if

the increased vibration level cannot be detected in flight.”

The FAA considered

this special condition satisfied with its acceptance of a GE

certification report that concluded that CF6-45/-50 engine unbalance

levels high enough to have detrimental effects would be easily

detectable by perceived noise and vibrations in the cabin area and in

the controls, enabling the flight crew to take corrective action.

However, the

flight crews of the airplanes that experienced the uncontained CF6-50

LPT S3 disk failures cited above did not report any unusual engine

vibration preceding the events. In addition, there were no reports of

vibration associated with the removal-from-service of the eight CF6-50

engines in which the cracked LPT S3 disks were discovered during normal

teardowns.

Thus, the NTSB

concludes that GE’s FAA-approved special condition has failed to provide

an adequate margin of safety to prevent catastrophic CF6-45/-50 LPT S3

disk failure. Therefore, the NTSB recommends that the FAA immediately

require GE to redesign the CF6-45/-50 LPT S3 disk so that it will not

fail when exposed to HP rotor unbalance forces.

The NTSB also

recommends that, once GE has redesigned the CF6-45/-50 LPT S3 disk in

accordance with Safety Recommendation A-10-100, the FAA require all

operators of CF6-45/-50-powered airplanes to install the newly designed

LPT S3 disk at the next maintenance opportunity.

Therefore, the

National Transportation Safety Board recommends that the Federal

Aviation Administration:

Immediately

require operators of CF6-45/-50-powered airplanes to perform high

pressure turbine rotor blade borescope inspections every 15 flight

cycles until the low pressure turbine stage 3 disk is replaced with a

redesigned disk that can withstand the unbalance vibration forces from

the high pressure rotor. (A-10-98) (Urgent)

Require operators

of CF6-45/-50-powered airplanes to perform fluorescent penetrant

inspections of CF6-45/-50 low pressure turbine stage 3 disks at every

engine shop visit until the low pressure turbine stage 3 disk is

replaced with a redesigned disk that can withstand the unbalance

vibration forces from the high pressure rotor. (A-10-99)

Immediately

require General Electric Company to redesign the CF6-45/-50 low pressure

turbine stage 3 disk so that it will not fail when exposed to high

pressure rotor unbalance forces. (A-10-100) (Urgent) |

| Other News Stories |

|

|

| ©AvStop

Online Magazine

Contact

Us

Return To News

|

|