|

|||||||||||||||||

|

|

|

|||

|

By Jim Douglas |

||||

|

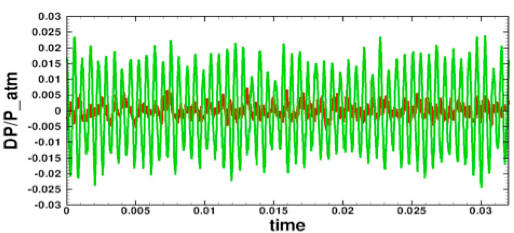

February 18, 2011 - Advanced military jet aircraft have

engines that provide the needed speed and

maneuverability. However, with this greater power there

is significant noise during takeoff and landing.

The noise can impact the public and affect the health

and safety of flight line workers. To confront the

challenges of the noise problem, the Naval Research

Laboratory (NRL) collaborated with the University of

Cincinnati (UC) and GE Aircraft Engines to investigate

the use of mechanical chevrons (serrations at the rim of

the exhaust nozzle) and fluidics to successfully reduce

the noise from supersonic military jet aircraft.

The initial research, sponsored by the Strategic

Environmental Research and Development Program (SERDP),

revealed the potential for significant noise reduction

of high performance jet engines without compromising

performance or environmental standards. |

|||

|

SERDP is

DoD?s environmental science and technology program, planned and

executed in partnership with DOE and EPA. The Navy recognized

this research as a Top Twenty Research Accomplishment of 2009.

Their

findings revealed that the spacing of the shock cells and the

length of the core increased as the ratio of the pressure inside

the nozzle to the pressure outside (total pressure ratio)

increased. These results were confirmed by experimental data

from UC, showing that computational analysis works in assessing

the effectiveness of chevrons and fluidics.

The

research team published their finding in the American Institute

of Aeronautics and Astronautics journal and received a 2009 Alan

Berman Research Publication Award for outstanding archival

research, as judged by NRL management. |

||||

|

|||||

|

|

|||||

| ?AvStop

Online Magazine

Contact

Us

Return To News

|

|||||

|