|

|||||||||||||||||

|

|

|

|||

|

By |

||||

|

March 21, 2011 - There is no question airlines have been struggling financially over the last ten years. Many over the years have blamed organized labor for being inflexible and unwilling to lower costs.

Unfortunately, in a knee jerk response in an attempt to

lower costs, many airlines have outsourced thousands of

high skilled jobs to aircraft maintenance repair

companies that are not tightly regulated or inspected by

the Federal Aviation Administration (FAA) as those

maintenance divisions run by the air carriers

themselves.

For example, in 1999 American, United, Northwest, US Airways, Delta, TWA, and Continental all performed the overwhelming majority of their aircraft maintenance work in-house. |

|||

|

Regional

airlines also kept a large portion of their work internal and

within the

A

significant amount of wide body aircraft are currently being

sent to

In the

latest OIG report, out of eight major airline FAA inspection

offices in the Each year the problem of inadequate oversight, strained government resources, and lack of consistent application of standards may put passengers at risk. At American Airlines, the TWU is resisting the industry wide outsourcing trend. Other companies have outsourced, while some airlines along with their Unions representing the workers were unwilling to look for solutions to preserve these jobs. |

||||

|

The TWU Membership

has worked to find unique ways to lower the costs of keeping work

in-house while maintaining high quality workmanship. At the same time,

the AFL-CIO Transportation Trades Department continues to pursue

legislation to hold all aircraft repair stations and airlines to a

uniform standard at the federal level. The standard of safety must be

equal for all operators, regardless if they are

This report seeks

to enlighten each person who flies as to whether he or she can be sure

the aircraft carrying them is being maintained to the highest standards.

Can you safely say the aircraft you?re flying on is maintained by people

who have under gone thorough security background checks, drug screening,

training, and can understand the maintenance manuals they are using? If

you fly American Airlines you can rest assured, TWU represented aviation

maintenance professionals are hard at work maintaining your aircraft to

the highest standards.

Many airlines have

responded to the need to cut costs by cutting wages, reducing benefits,

eliminating pensions along with outsourcing in-house aircraft repair,

resulting in massive job losses. Outsourcing aircraft repair has to be

the biggest concern to the traveling public because the FAA lacks the

resources, or a well structured oversight system to adequately ensure

aircraft maintenance is done properly.

Labor Unions are

not the only organizations raising concerns about this fact -- the U.S.

Office of the Inspector General (OIG) has repeatedly raised this issue

uring the last decade. Unfortunately, to date, a majority of the serious

safety issues raised by the OIG have not been addressed; several

critical safety issues raised are seven years old.

On another serious

note, what is the standard for personnel working on aircraft when the

aircraft repair is outsourced to a repair station?

The FAA does have

the ability to perform inspections overseas; however, the number of FAA

Inspectors is woefully insufficient. Many facilities outside the

This report seeks

to inform people about the need to take a very hard look at the system

in place for ensuring the safest possible transportation system for all

whom fly. Transport Workers Union Members are some of the most

experienced, well-trained professionals in the aviation world. Organized

labor did not create the aviation maintenance rules and regulations, but

we have worked to make sure these rules are clear, are applied

reasonably, and uniformly.

Prior to 2001, the

majority of The term ?gold plate? was used in the industry for their aircraft since in-house employees took ?pride of ownership.? Training was conducted consistently and often, the vast majority of aircraft maintenance technicians were FAA licensed, drug tested, and FAA inspectors would show up frequently to ensure proper compliance with safety regulations.

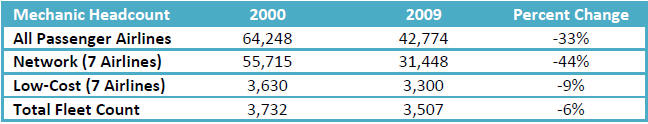

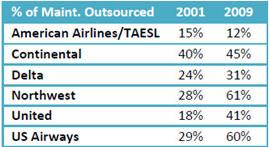

This all radically

changed with the wave of bankruptcies that occurred early on in the

first half of the last decade. United, Delta, and US Airways, to name a

few, gutted labor agreements, pay and benefits were slashed. Most

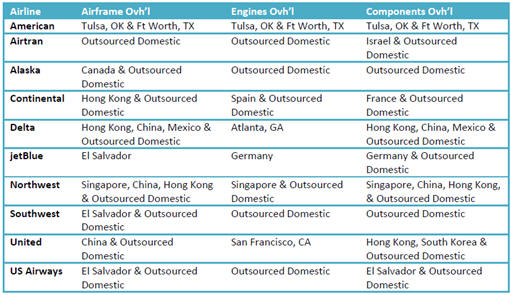

airlines sent a major portion and in some cases all -- of airframe

overhaul to outside providers of maintenance.

There is one way

to ensure your aircraft has been maintained in the U.S. by trained,

qualified, background checked, drug tested, experienced professional FAA

licensed mechanics. At American Airlines, TWU Members have worked hard

to ensure every plane is maintained to the highest possible standards

set by the FAA. In many cases, AA goes above and beyond to ensure every

aircraft is safe and reliable.

At American

Airlines overhaul bases in

There is a

language barrier problem in these operations. Large numbers of employees

at these foreign facilities do not speak English. This wouldn?t be a

problem except the international language of aviation is English. Many

of these foreign facilities do not translate the maintenance manuals and

paperwork into the workers? native language, but instead require one of

the FAA licensed mechanics to translate. You could imagine how hard it

would be at a facility like AMECO where one mechanic is responsible for

500 unlicensed mechanics.

The Transport

Workers Union and American Airlines have collaborated to find innovative

ways to control and lower cost, obtain high quality, and keep highly

skilled jobs in

For example,

management and mechanics at United and Northwest decided to fight any

type of change and ended up with catastrophic sacrifices. At United,

airframe overhaul was substantially outsourced resulting in a reduction

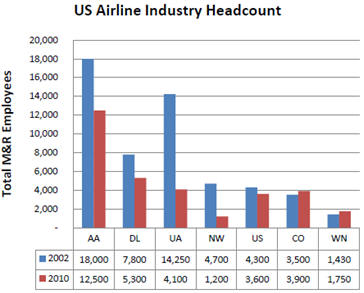

of more than 50% in the mechanic and related workforce.

The end result at

Northwest was even worse. The

In the end, 6,000

aircraft mechanics lost their jobs and all aircraft maintenance work was

outsourced except for two stations ?

At Southwest, the

most profitable airline of major passenger carriers, the outsourcing

problem persists. Work restricted under an earlier agreement negotiated

by a predecessor Union to only North American facilities is now being

sent to Aeroman in

Aircraft Mechanic

positions at Southwest are now capped at 2.75 per aircraft, without

regard to whether the work can be completed more effectively by in-house

aircraft mechanics.

The mass

outsourcing of aircraft overhaul maintenance and the resulting closure

of a majority of domestic aircraft maintenance facilities operated by

U.S carriers has impacted all mechanic and related personnel. Highly

skilled facility and automotive technicians, along with their

experienced and capable support personnel, have been furloughed

numbering into the thousands. Properties they maintained have been

shuttered or sold. Most air carriers have now completely discarded this

crucial function to limit their maintenance operations to the bare

minimum.

Many observers

have argued Unions are the cause of all the job, wage, and benefit

losses at airlines mentioned. That would not be a true statement.

Non-Union Delta airlines made the same choice to outsource aircraft

maintenance work by substantially shedding airframe overhaul repair. The

driving factor in the decision to outsource was obviously the reduced

exposure to

? TIMCO ?

maintenance contractor for United, Delta, and US Airways ? was found to

have multiple employees working on critical aviation maintenance

structures that had falsified immigration documents. The employees were

caught in 2005 during a federal investigation. ? On November 18, 2009 the Transportation Security Administration (TSA) issued a Notice of Proposed Rule Making (NPRM) to address the significant gaps on security that exist at repair stations. Currently those employees that do not have access to the airfield operations area do not have to undergo security background checks; however, they are allowed to work on safety sensitive structure, engines, and components.

? In 2003 at a

? In January 2011,

FAA has proposed a $1.025M fine of ST Aero for hiring 90 repair station

employees at its

The work they

performed has not been moved to facilities with equal skill and

capabilities. Overhaul work for United, US Airways, and Delta is now

done in countries like China, El Salvador, Singapore, and Mexico, to

name a few, and the standard of work being performed by these facilities

is often not of acceptable quality. For example, read the following

issues that have come up in recent years:

? US Airways

mechanics found incidents of door components installed backwards and

crossed wires for critical engine instrumentation. All this work was

conducted at Aeroman in

During a NPR

interview Aeroman mechanics stated that many did not speak English even

though the manuals are not in Spanish.

? The OIG stated

in their 2003 report that of the repair stations visited, 38 percent did

not maintain training files for supervisory personnel that were

overseeing the work performed.

? Aeroman

mechanics say managers kept pressuring them to fix the planes faster.

For instance, if there's rust on a metal beam, but it's just a little

over tolerance, "the supervisor says, 'Oh, just leave it like that,' "

the mechanic says, through an interpreter.? 'There's no need to repair

it.

? The 2003 OIG

report AV-2003-047 detailed an incident (airline de-identified) of an

aircraft operated by a

While some labor

Unions seem to have given up on the fight10, the TWU (AA Mechanics

Union) continues to push for uniform standards for all aircraft

maintenance facilities. The TWU continues to lobby for stricter

standards for all FAA licensed repair stations. The issue is not

protectionism, but safety, and the need for a single standard of safety.

At the same time

air travel was becoming more common place, aviation technology improved.

The aircraft became safer, but they also became more complex to

maintain. Composite materials, advanced avionics, and new maintenance

information technology are now the rule instead of the exception. There

has also been a shift in how aviation maintenance is being monitored for

compliance with the safety regulations.

The ATOS system in

place was still evolving and the major financial crisis at nearly all

the airlines was unprecedented. The FAA did not have the resources to

meet the demand for increased inspections that were needed as the

problems got worse. United, US Airways, and Delta dropped most, and, in

some cases, all airframe overhaul at Northwest they went even further by

outsourcing all airframe and engine overhaul along with line maintenance

at all but two cities. Outsourcers of aircraft maintenance promised

airlines they could handle the new influx of work.

The FAA had

implemented ATOS on airlines that performed most of their maintenance

in-house, but this changed overnight. Safety oversight was now severely

strained and the financially strapped airlines decided costs needed to

be lowered further. Maintenance on nearly all wide body aircraft and

some narrow body aircraft was moved to foreign repair stations.

The FAA did not

have the inspection staff in place to cover this occurrence and airlines

and the FAA did not move to adapt ATOS to properly oversee the change in

work responsibility. The OIG had already signaled concerns about

oversight and now the issues were magnified many fold.

? The NTSB12in

1997 recommended to the FAA that it 1) ensure that passenger aircraft

maintenance receives the same level of FAA oversight, regardless of

whether it was performed in-house or by repair stations 2) review the

workload of inspectors assigned oversight responsibility for repair

stations to ensure those inspectors have sufficient time and resources

to perform surveillance.

? In the 2003 OIG

report AV-2003-047, it was noted that the FAA inspected one major

? Also in the OIG

report AV-2003-047, the report stated that ??the FAA has no mechanism in

place to obtain information on how much work is outsourced, domestically

or overseas. FAA inspectors believe it is not part of their oversight

responsibility to track this information.?

? FAA inspector

staffing and budget problems are hampering the oversight process. At

five of the nine major air carriers reviewed, the OIG was told they

could not perform their tasks due to the constraints of the current

budget. One inspector was so constrained the office was only able to

inspect 16% of one carrier?s substantial maintenance providers.

? The OIG reported

again in 2010 that the FAA was not able to get their required

inspections accomplished. During the period of FY2005 and FY2009,

inspectors at 8 major

? The FAA is not

following its own risk assessment guidance. During the merger of

Northwest and Delta the FAA rated neither of those airlines as a higher

risk even though the FAA lists ?Merger or Takeover? as an area of

increased risk and stepped up inspections were required.

? During the

period of FY2002 to FY2009 the US Airways inspection office completed

slightly less than 25% of its inspection workload. US Airways outsourced

60% of their total maintenance spend in FY2009.

One can easily

tell the problems and issues are well documented; however, the FAA has

not caught up to the changing airline environment. There are

insufficient inspectors for foreign repair stations and there is no way

they can adequately and uniformly ensure the same level of compliance at

all repair stations foreign and domestic.

The FAA clearly

has work to do to ensure airline passengers can be assured their

aircraft has been maintained to the same standard of quality and

compliance. Under the current system of controls and oversight, unless a

passenger is flying on American Airlines, the chances are the aircraft

they?re on was maintained by a repair station which may or may not have

been inspected within the last five years.

Is There A

Solution? How Can The Public Be Reassured Their Aircraft Is As Safe As

Possible?

Under the current

regulatory system there are no assurances. There is hope, the TWU, the

AFL-CIO Transportation Trades Department and its affiliates have been

working together to get the aviation safety system working right. The

The TWU through

the Transportation Trades Department has advocated for stricter

legislation for drug testing, uniform standards of repair station

licensing, and security background checks for anyone who work?s on an

aircraft, engines, and components regardless of whether or not the

employee is on or off the airport area of operations.

While many

lobbyists for independent repair stations and Corporation?s would say

Unions want to protect their member?s jobs at the expense of affordable

air travel, consistent uniform safety standards are the best possible

protection for the traveling public. The following reforms are necessary

to achieve this standard;

? Require that all

maintenance on all

? Require, as a

condition of FAA certification, all repair stations meet the same

standards. This would include, but not be limited to, drug and alcohol

testing and Part 65 aircraft mechanic certification, background checks

etc.

? Reconfigure FAA

inspection and oversight to place the greatest scrutiny on those repair

stations whose audits determine to pose the greatest risk to safety and

security.

? Require, as a

condition of FAA-certification, all repair stations be subject to

unannounced FAA inspections. The FAA shall be prohibited from certifying

any repair station in any countries that prohibit unannounced

inspections and shall immediately revoke any existing certifications in

these countries.

While these points

are merely a short list, there are legislative actions already moving

forward at this time. The FAA Reauthorization Bill has been discussed

and reworked but has yet to be voted on by both houses of Congress. The

TSA has also issued a Notice of Proposed Rule Making on repair station

security that needs to move forward so passengers can be assured the

work done on the aircraft was done by people who have been thoroughly

screened. The traveling public has a right to demand safe air travel and

the government?s role must be to ensure that safety is not compromised.

Leveling the

Playing Field - A TWU Priority- The TWU understands the obstacles labor

faced during the past decade. There have been pay concessions, loss of

pensions, huge job loss at a majority of the air carriers and

significantly more expensive health care.

As the largest

single organized aircraft maintenance labor group in the

We are now working

to set a clear direction with goals and campaigns developed by the

AFL-CIO Transportation Trades Department. In addition, we are working

with our new labor Coalitions, the (IBT) International Brotherhood of

Teamsters and (CAPA) Coalition of Airline Pilots along with the (APA)

Allied Pilots Association and (APFA) Association of Professional Flight

Attendants at American, to persuade Congress, the FAA, and the

Department of Transportation to preclude substandard aircraft

maintenance by requiring the proper oversight by the FAA and other

greatly needed safety and security measures.

All this to ensure

the

On Capitol Hill,

concerned legislators have been working to correct the problems with the

current Federal Aviation Regulations. The FAA Air Transportation and

Safety Improvement Act (S223) passed the Senate in February 2011, but

with several anti-worker amendments. The new bill has been weakened

significantly however.

Foreign repair

station inspections have been reduced to ?risk-based? versus required

and the U.S. Secretary of State and Secretary of Transportation only

?request? not require drug and alcohol standards for foreign repair

stations that work on the The risk-based system is flawed as noted in the OIG 2008 and 2010 reports16 and until the system is corrected, the FAA should be conducting the inspections. The House is moving forward with their version of the bill (HR658) which is more anti-worker than the Senate bill and seeks to liberalize inspections, drug testing, and background checks even further.

There is even an

amendment to the bill seeks to repeal the changes by the National

Mediation Board (NMB) that make Union organizing election rules more

reasonable. The bill should focus on improving aviation safety and

security not partisan politics or business lobbyists who want profits

with no consideration to for the private citizen?s well-being.

Enough is enough!

The public, as well as all aviation professionals should be extremely

concerned. The government must determine an acceptable set of standards

to ensure the traveling public?s safety. If drug and alcohol testing,

security background checks, and frequent compliance inspections by the

FAA is not important enough to do abroad, then why do it at home in the

U.S. to airline owned aircraft maintenance repair facilities? The answer is simple, any reasonable person wants a drug free, fully screened, and closely monitored aircraft mechanic responsible for working on their aircraft as it flies at 30,000 feet at over 500 MPH. Every American should be appalled at the compromises being made, while other federal watchdog agencies like the Inspector General and NTSB have pointed out for over ten years specific issues must be addressed.

What can you do?

Contact your Representatives and Senators today and let them know your

safety and security is important and to pass the bills S223 and HR658

without the new amendments. The current bill with amendments weakens the

FAA?s ability to ensure acceptable standards of safety and security. Act

now!

At the bargaining

table, the TWU is working hard to ensure the Membership we represent

reaps the benefits of their hard work, financial sacrifices, and

increased productivity. This goal will be achieved through a unified

effort of all TWU brothers and sisters.

At AA these

contract negotiations are our number one priority, no matter how

frustrated we are with the process dictated by the Railway Labor Act and

the extended time we have been in mediation/negotiations. We must

remember at this critical time to respect one another?s opinion. At the

same time make sure the inevitable and necessary debate among ourselves

is based on accurate information and fact rather than innuendo, and

motivated by a true desire to move the Membership forward.

In closing, no

matter how daunting the task before us may seem, no matter how this

industry may have betrayed our thoughts and dreams of how we envisioned

our careers, no matter how many times we hear from people that have not

been in the arena and claim to have all the answers, it is best to

reflect back to some of the best advice provided by the founder of our

Union: |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ?AvStop

Online Magazine

Contact

Us

Return To News

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||